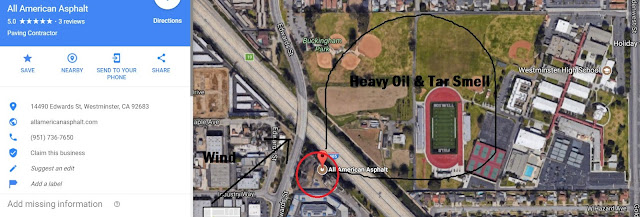

Toxic tar & oil smell on the fields at Westminster High School from All American Asphalt.

We located a business All American Asphalt across the 405 freeway that is the likely culprit of the smell. I am shocked that no one else had written about this issue. The wind was blowing right across the freeway in our direction of about 3 soccer games, 3 baseball practices and a football stadium track being used. The smell was absolutely horrible.

The smell associated with melting tar or asphalt can vary but is often described as a strong, distinct odor. When tar or asphalt is heated or melted, it can release volatile organic compounds (VOCs) into the air, which contribute to the smell.

Producing asphalt involves a complex process that requires specialized equipment and facilities. Here's a simplified overview of how asphalt is typically made:

Aggregate Preparation: Aggregates, such as crushed stone, sand, or gravel, are selected and processed to meet the desired specifications. This includes cleaning, crushing, and screening the aggregates.

Drying: If the aggregates contain moisture, they need to be dried to ensure proper asphalt mixing. This is typically done in a rotating drum dryer.

Heating Bitumen: Bitumen, a sticky black substance, is heated in a separate chamber or tank to make it more fluid for mixing with aggregates. Bitumen is a petroleum-based product.

Mixing: The heated bitumen is then combined with the dried aggregates in an asphalt mixing plant. The plant typically has different compartments or bins for various sizes and types of aggregates. The aggregates and bitumen are mixed together in controlled proportions to achieve the desired asphalt mix.

Storage: The hot asphalt mix is transported to storage silos or trucks for further use or delivery. It needs to be stored and transported at a high temperature to maintain workability.